Manufacturing

Advanced

Technology

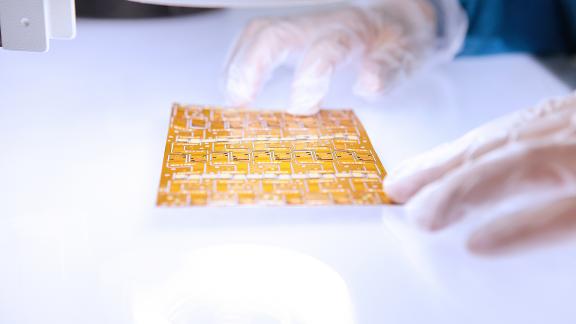

PCBs

At Winonics we serve people, not markets. Our advanced technology and quick turnaround meet your needs for quality products, on time and without excuses. The resulting valuable and reliable solution gives you the competitive advantage your company requires.

We set the highest standards for conventional and advanced technology multilayer PCBs and by consistently investing in innovative engineering solutions and advanced process capabilities.

We are committed to providing convenient and easy access to tools, documentation, support, and up-to-date learning resources to proactively equip and contribute to our partners success.

Winonics is an invaluable resource in your pursuit of innovative product solutions. From prototyping through dependable full-scale production, our engineering and manufacturing resources are here to ensure that your product, meets or exceeds your expectations every step of the way.